What We Do

We offer a comprehensive range of services, including design, fabrication, construction, special projects, and service/maintenance. Our commitment to quality craftsmanship and innovation is demonstrated through our use of advanced technologies like the HGG ProCutter and Novarc SWR™, which enhance precision, productivity, and safety.

Services

Construction & Special Projects

Our team excels in managing and executing complex construction projects with precision and efficiency. From large-scale builds to unique special projects, we handle every aspect with the highest standards of quality and safety. We work closely with clients to deliver on-time and within budget, ensuring that each project meets their specific needs and exceeds expectations.

Service & Maintenance

We offer comprehensive service and maintenance solutions to keep your systems running smoothly and efficiently. Our skilled technicians are available to address any issues, providing preventative maintenance and prompt repairs. Whether it’s routine inspections or emergency services, we ensure your systems operate at peak performance.

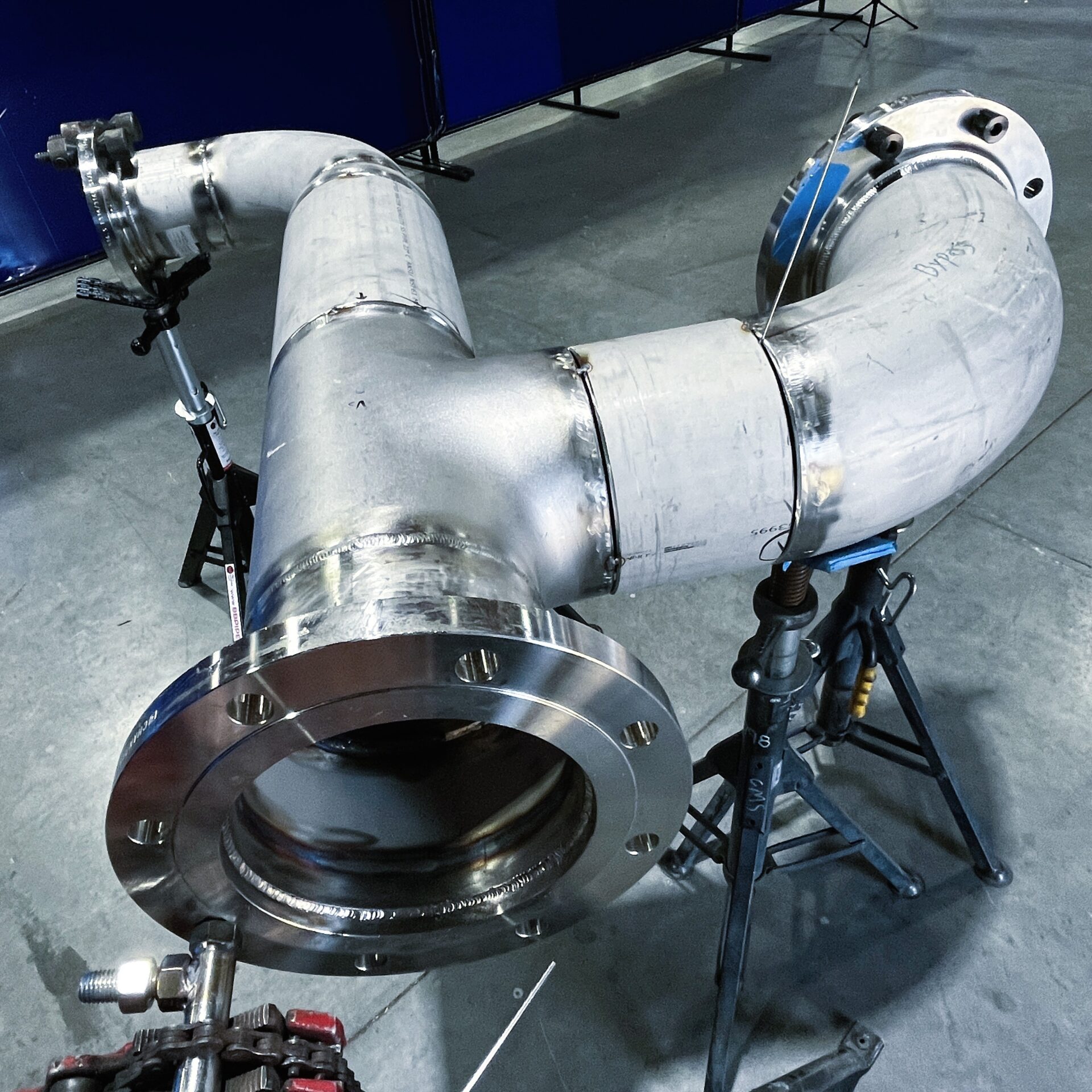

Design & Fabrication

Our design and fabrication services bring innovative solutions to life. Our in-house design team collaborates with clients to develop customized systems that meet their unique requirements. Our state-of-the-art fabrication shop allows us to create high-quality, durable components with precision.

Markets

Mission Critical

Industrial

Commercial

Fabrication

Solutions

HGG ProCutter 900 RB

The HGG ProCutter 900 RB in our shop allows us to deliver custom-fabricated systems more efficiently and accurately. This advanced CNC pipe-cutting machine handles various pipe sizes and materials, enabling complex cuts and bevels. This investment demonstrates our commitment to offering innovative and reliable fabrication services for our projects.

Novarc Spool Welding Robot (SWR™)

This state-of-the-art robotic welding arm is a game-changer for our industry. It helps us:

- Boost Productivity: Novarc SWR™ can increase pipe welding productivity by 3-5 times for carbon steel and up to 12 times for stainless steel.

- Enhance Quality: The SWR™’s precise movements and automated features eliminate errors and ensure consistent, high-quality welds for even the most complex jobs.

- Improve Safety: The SWR™ protects our workers from fatigue and minimizes potential burns, eye damage, electrical shock, cuts, and other such injuries associated with welding.

- Promote Collaboration: The Novarc welding robot works alongside our master welders in a shared workspace. The robot can handle extreme repetitive and strenuous welding tasks, allowing our welders to focus on more skilled aspects of the job.

Topcon FC 5000 Site Robotic Layout

We use GPS and laser robotics to help us plan, scan, measure, and level our jobsites for precision construction layout and increased efficiency. Digital technology eliminates traditional layout methods of pulling tape and setting string line. This allows us to immediately discover where adjustments need to be made in the field in real time, eliminating costly rework and keeping our projects on track.

BIM Modeling

We provide 3D-7D Building Information Modeling (BIM) services for the lifecycle of your construction project or specific use-cases. Our team harnesses the many benefits of BIM to improve site planning, enhance visualization of the entire project, streamline communication and collaboration between disciplines, reduce instances of rework and revisions, provide accurate cost estimation and budget tracking, and heighten safety and efficiency.

Specialty Welding

Our professional welders are trained and certified in national codes and standards. Our capabilities cover a wide variety of welding materials including carbon steel, cast iron, low alloy steel, high alloy steel, aluminum-based alloys, nickel-based alloys, and copper piping. We understand that welding solutions are unique to each project, so our skilled craftsmen implement top of the line solutions and follow strict safety and welding procedures.

Controls

We engineer, install, and service both mechanical systems and corresponding controls systems for a complete turn-key building automation management solution. From simple customizable HVAC controls to advanced tools, our properly engineered controls systems are customized to fit your project’s needs and maximize health, comfort, efficiency, savings, and safety. We deliver intuitive, powerful tools for controlling and monitoring the most critical and complex mechanical systems for any building type or size.

Safety

Our commitment to zero incidents is reinforced through our culture and attitude towards safety. We pride ourselves on our unwavering focus to provide continuous safety instruction and certified training.

We are proactive when it comes to ensuring the safety of our employees and the safety of others. We are dedicated to the strict adherence of Federal and State Safety Regulations and follow stringent safety protocols while maintaining quality and productivity. Our business is proud of our safety record and our unwavering commitment to a zero-injury workforce.

Safety is of the utmost importance and a significant part of our daily life. Our reputation relies heavily on our team and our conduct, from the office to the field and everything in between. We evaluate each project’s unique circumstances and safety protocols to properly prepare our team and keep everyone on or near the site as safe as possible.

By maintaining the highest level of safety, we achieve the best possible outcome for our team and our clients.